Motor

Be sure your power supply agrees with the nameplate marking. Voltage decrease of more than

10% will cause loss of power and overheating. D

EWALT tools are factory tested; if this tool does

not operate, check power supply.

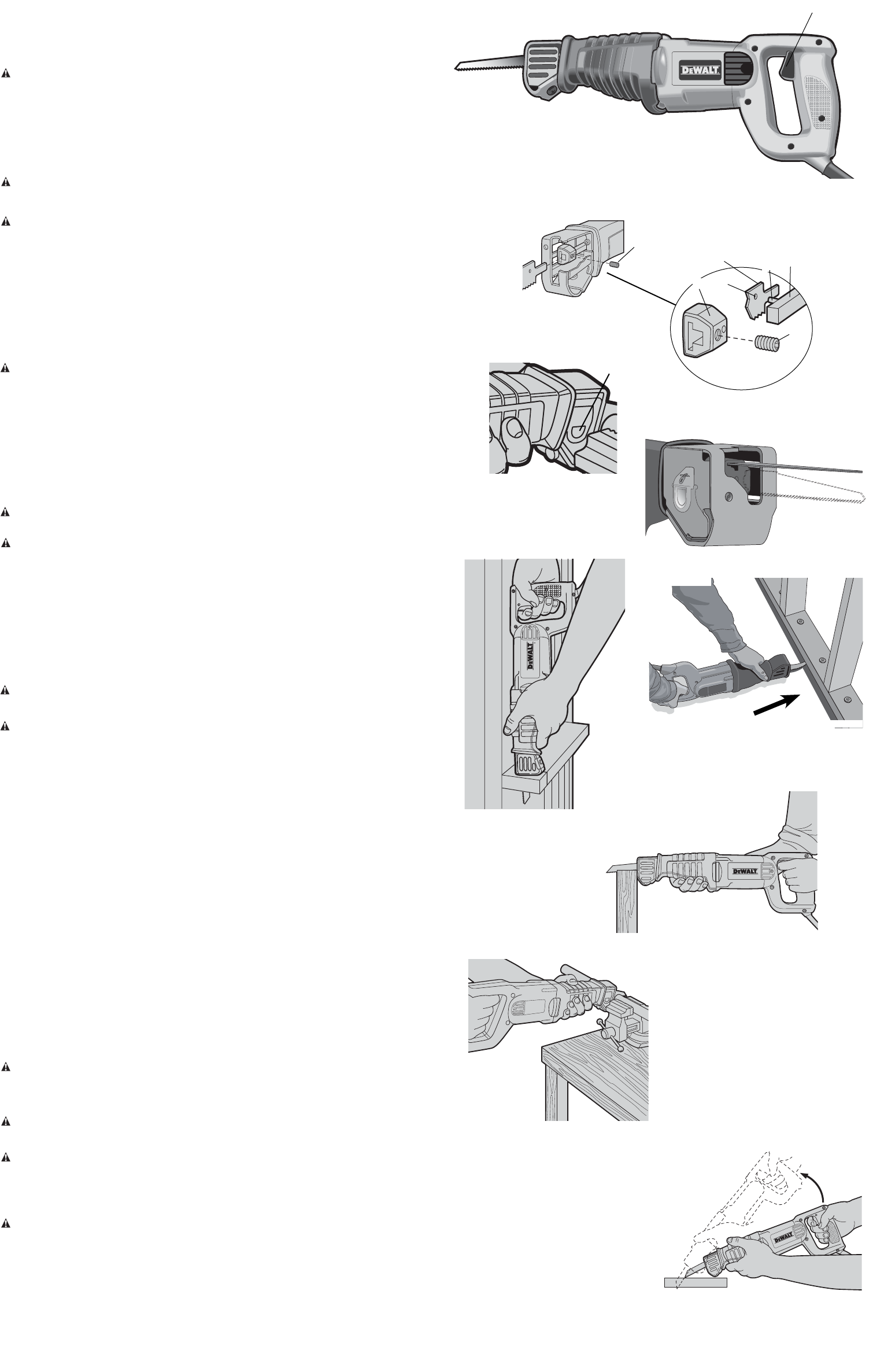

COMPONENTS (Fig. 1–3)

WARNING: Never modify the power tool or any part of it. Damage or personal injury could result.

A. Trigger switch E. balde clamp

B. Set screw F. Blade

C. Blade shank G. Pin

D. Reciprocating shaft H. Blade clamp release lever

Switch (Variable Speed) (Fig. 1)

The variable speed trigger switch (A) will give you added versatility. The further the trigger is

depressed the higher the speed of the saw. To turn the tool “OFF” release the trigger.

CAUTION: Use of very slow speed is recommended only for begin ning a cut. Prolonged use at

very slow speed may damage your saw.

ASSEMBLY AND ADJUSTMENTS

WARNING: to reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

Blade Clamping (Fig. 2)

(DW303)

TO INSTALL BLADE INTO SAW

1. Loosen set screw (B).

2. Insert blade shank (C) from the front between the reciprocating shaft (D) and the blade clamp

(E). Locate hole in blade (F) over pin (G) on reciprocating shaft.

3. Tighten set screw. If the blade should break off and the shank does not come out of the clamp,

be sure the set screw is loose and eject the shank with a nail or pointed object.

CAUTION: THE BLADE GUARD IS THERE FOR YOUR SAFETY. DO NOT REMOVE IT.

Blade Clamp Release Lever (Fig. 3)

(DW303M, DW304P, DWE304)

TO INSTALL BLADE INTO SAW

1. Pull blade clamp release lever (H) up.

2. Insert blade shank from the front.

3. Push blade clamp release lever down.

TO REMOVE BLADE FROM SAW

1. Open blade clamp release lever.

2. Remove blade.

CAUTION: THE BLADE GUARD IS THERE FOR YOUR SAFETY. DO NOT REMOVE IT.

OPERATION

WARNING: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

Cutting with Blade in Horizontal Position (Fig. 4A)

(DW304P, DWE304)

Installing a blade in the horizontal orientation allows cutting close to floors, walls or ceilings where

limited clearance is available. Ensure that the Blade Guard is pressed against the framing to avoid

kickback.

Flush-To Cutting (Fig. 5)

The compact design of the saw motor housing and spindle housing permits extremely close cutting

to floors, corners and other difficult areas.

CAUTION: When sawing into walls, floors or wherever “live” electrical wires may be encountered,

DO NOT TOUCH ANY FRONT METAL PARTS OF THE TOOL! Hold the tool only by the plastic

handle and housing to prevent electric shock if you saw into a “live” wire.

CAUTION: Always wear eye protection while operating this power tool.

Wood Cutting (Fig. 6)

Before cutting any type of wood, be sure it is firmly anchored or clamped to prevent slipping. Place

blade lightly against work to be cut, switch on saw motor and allow it to obtain maximum speed

before applying pressure. Always hold saw firmly with both hands while cutting. Whenever possible,

the saw shoe must be held firmly against the material being cut. This will prevent the saw from

jumping or vibrating and minimize blade breakage.

Metal Cutting (Fig. 7)

This unit has different metal cutting capacities depending upon type of blade used and the metal

to be cut. Use a finer blade for ferrous metals and a coarse blade for non-ferrous materials. In thin

gauge sheet metals it is best to clamp wood to both sides of sheet. This will insure a clean cut

without excess vibration or tearing of metal. Always remember not to force cutting blade as this

reduces blade life and causes costly blade breakage.

NOTE: It is generally recommended that when cutting metals you should spread a thin film of oil or

other coolant along the line ahead of the saw cut for easier operation and longer blade life.

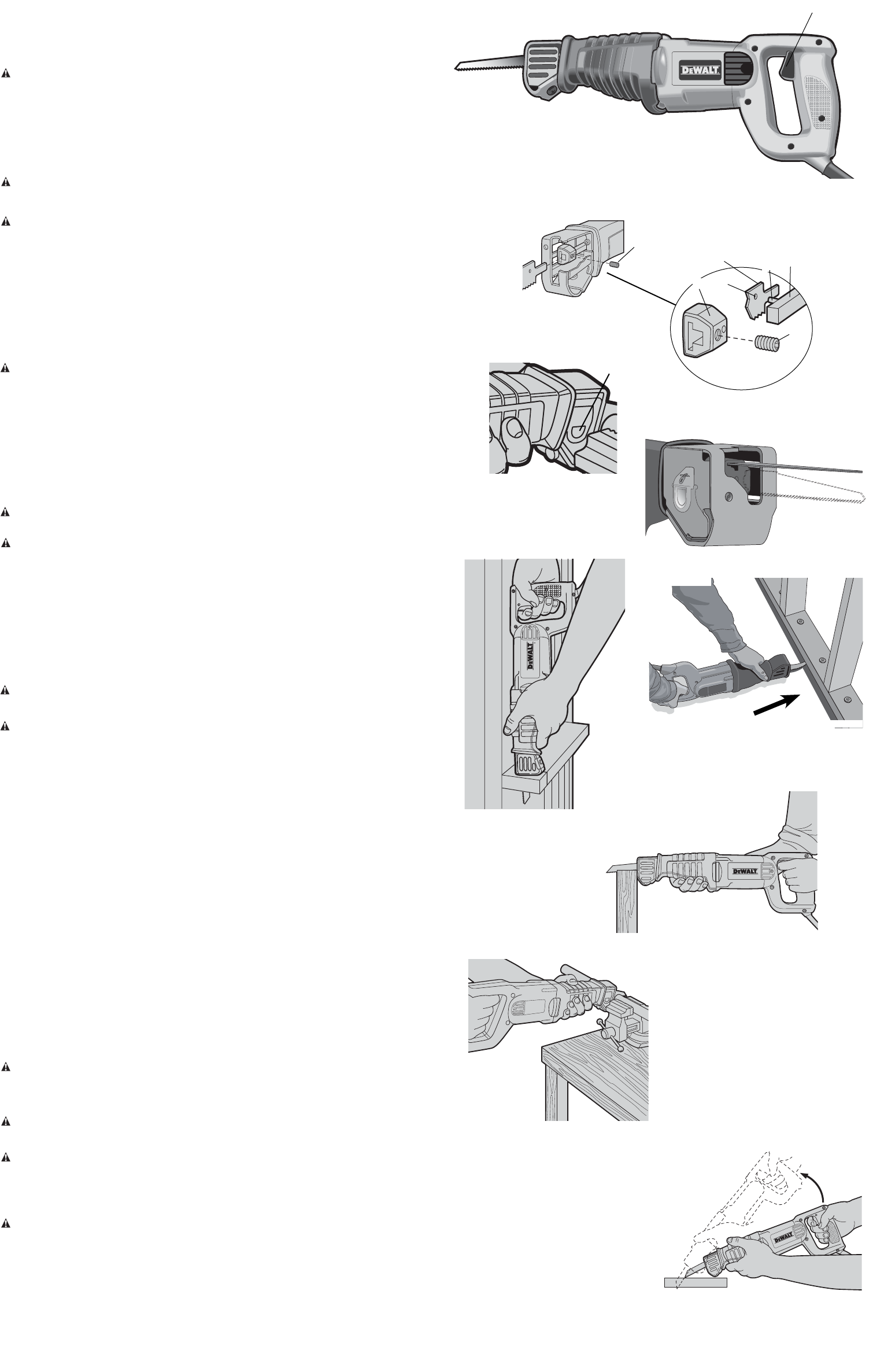

Pocket Cutting (Fig. 8)

(Wood Only)

The initial step in pocket cutting is to measure the surface area to be cut and mark clearly with a

pencil, chalk or scriber. Insert pocket cutting blade in blade clamp and tighten blade clamp securely.

Next, tip the saw backward until the back edge of the shoe is resting on the work surface. Now

switch motor on, always permitting blade to attain maximum speed. Grip handle steadily and begin

a slow, deliberate upward swing with the handle of the saw. Blade will begin to feed into material.

Always be sure blade is completely through material before continuing with pocket cut.

NOTE: In areas where blade visibilty is limited, use the edge of the saw shoe as a guide. Lines for

any given cut should be extended beyond edge of cut to be made.

MAINTENANCE

WARNING: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

Cleaning

WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week. To

minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when performing

this.

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts of

the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested with

this product, use of such accessories with this tool could be hazardous. To reduce the risk of injury,

only D

EWALT recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local dealer or

authorized service center. If you need assistance in locating any accessory, please contact D

EWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-D

EWALT (1-800-

433-9258) or visit our website: www.dewalt.com.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush

inspection and replacement) should be performed by a DEWALT factory service center, a DEWALT

authorized service center or other qualified service personnel. Always use identical replacement

parts.

FIG. 7

FIG. 4

FIG. 6

FIG. 1

H

FIG. 3

FIG. 8

ROCK TOOL UP TO NORMAL CUTTING POSITION

AFTER BLADE HAS CUT THROUGH MATERIAL

STARTING POSITION FOR POCKET CUTTING

POSITION DE DÉPART POUR LES COUPES

EN RETRAIT

POSICION DE INICIO PARA EL CORTE DE BOLSILLO

BERCER L’OUTIL EN POSITION NORMALE DE

COUPE ÁPRES AVOIR TRAVERSÉ MATÉRIAU AVEC

LA LAME

BALANCEE LA HERRAMIENTA HASTA LA

POSICION DE CORTE NORMAL DESPUES DE HACER

EL CORTE A TRAVES DEL MATERIAL

A

FIG. 5

B

C

E

D

B

FIG. 2

F

G

FIG. 4A